The difference between welding brazing and soldering isn’t significant when joining two or more metal pieces. So these methods are preferred when it comes to joining multiple metal structures. Most people think that a welder would require a heat supply for this process. But this field has as many secrets hidden under the curtain.

These methods certainly operate as a result of heat generation to join the metal pieces. But the difference remains as each method has its specific temperature range to carry out the process. Therefore, we’ll look up to some of the main key disparities that we have noticed here.

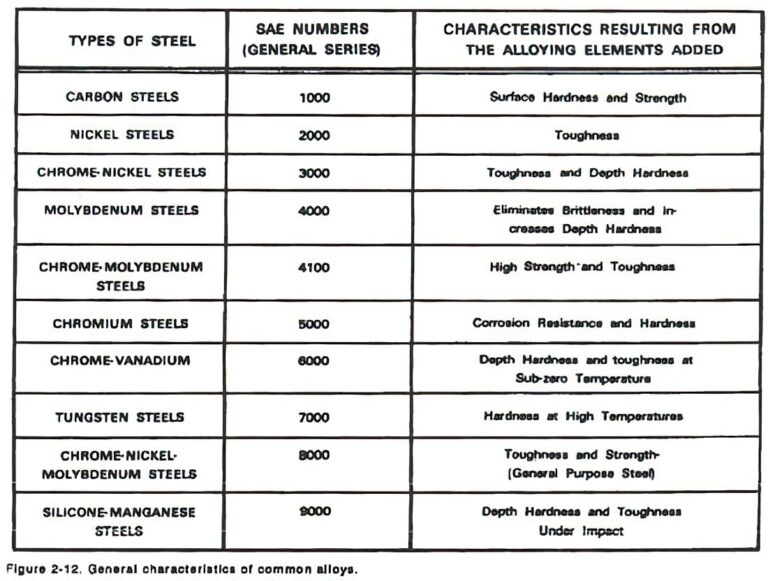

Table Representation: Welding vs. Brazing vs. Soldering

| Feature | Welding | Brazing | Soldering |

|---|---|---|---|

| Distortion | High distortion | Low distortion | No distortion |

| Power and Temperature | High power & high temperature | low power & low temperature | low power & low temperature |

| Strength of Joints | The high strength of joints | The low strength of joints | The low strength of joints |

| Thin Sections | A thin shield is hard to weld | A thin shield can be united | A thin shield can be united |

| Dissimilar Metals | Dissimilar metals are hard to weld | Dissimilar metals join easily | Dissimilar metals join easily |

| Base Metal Microstructure | Base metal’s microstructure change | Base metal’s microstructure doesn’t change | Base metal’s microstructure doesn’t change |

| Tensile Strength | Tensile’s strength > 200 MPa | Tensile’s strength 100 – 150 MPa | Tensile’s strength < 75 MPa |

| Base Metal Joining | Base metal welded | Base metal doesn’t join | Base metal doesn’t join |

What is Welding?

Welding remains the most known method in joining metal through heat. Wide usage of welding is for common materials that we use in the manufacturing of various important things. But before getting into its applications, let’s talk about welding as a process and its key highlights.

Welding comes out when the two metals/thermoplastics have a similar profile. That means a constituent like copper cannot be welded into steel. Therefore, this becomes the first main rule of the welding process. Moreover, the welding joins metal parts with a very high temperature as a condition for melting.

But the process must be carried out accurately by the welder to get sharp results. For example, if a welder operates by providing an excessive amount of heat, then metal properties will change for sure. This will result in an inaccurate process, and the welder won’t achieve a strong product.

Besides, wide usage of welding is to cut apart large metal bodies. This is an achievement by melting through the large metallic structure by providing a significant amount of heat. This way, the welders can slice apart the large metal structure through the process of welding.

Additionally, welding has many different types that depend upon the nature of the metal for processing. The types include inert metal gas (MIG), TIG, electron beam, arc, and stir friction in the end. Then people carry all these processes for different nature of the metals.

Welding runs our lives by processing many valuables such as bridges, buildings, and cars. Therefore, this process plays a significant role in fueling our everyday life by providing us many essential structures.

Advantages of Welding:

Most people trust welding for its capability to produce stronger and more resilient joints than the other methods. Adding more, the welded joints are suitable for high-temperature bearing applications. Therefore, this results in extra endurance and brilliant capability.

The welding is also capable of joining two metal sections that are thick or thin. This provides accurate results that we all love.

Disadvantages of Welding:

Your trusted process also has its drawbacks/disadvantages here. The process of welding results in huge thermal distortion while it leaves the residual stresses around the joint. This results in uneven areas around the processed joints.

It mostly joins similar metals as compared to brazing and soldering. Adding more, the joint residual stresses are required to relieve the post-processing heat process. Therefore, this makes welding a bit more assiduous to achieve accurate results.

What is Brazing?

Brazing is done mainly by joining two or more metal pieces by melting them and flowing a filler metal between the joint. It basically joins both pieces by melting a filler alloy to make a strong bond. The filler (Alloy) used in the method must have a low melting temperature than the joining metal pieces.

The brazing process is more famous and liked because of its great flexibility fueling many unique things. For example, people use brazing for joining dissimilar metals, unlike welding. The constituents like aluminum, copper, silver, gold, and nickel can participate in this process.

Adding more, people also use brazing in the process that promotes wetting. The filler conveniently flows over the joint parts when flu is there. Moreover, it functions efficiently to remove or clean parts of oxides. As a result, this cleaning provides a great foundation for the metal pieces to join strongly and tighter.

These fluxes hold significant importance in providing clean metal surfaces. Therefore, offering a clean and flawless joint process with no residual stresses like welded joints. Lastly, the brazed joints aren’t as strong as compared to the prime welded joints but offer a cleaner outlook with fewer efforts.

Adding more, the brazing method is also term as a high-temperature variant of the soldering method. The main brazing processes include vacuum brazing, torch brazing, induction brazing, and furnace brazing. Brazing has been widely used in modern industries in the joining of metal structures.

Brazing has major importance for its flexible nature as welders can join different base metals.

Advantages of Brazing:

The brazing method comes with a bundle of benefits occupying its vitality among most welders. The brazing method has low power input along with low processing temperature than the welding method in particular. Adding more, the brazing method does not require a post-heating treatment, unlike the welding process.

This coming advantage can mark the main difference between welding and brazing. Welders can now join dissimilar metals with the brazing process. As a result, its joints have minimal thermal distortion and residual stresses compared to welded joints with more residual stresses.

As a result, the joints are cleaned and don’t require additional heating treatments so that you can achieve the result with no extra effort.

Disadvantages of Brazing:

Your efficient brazing process has some drawbacks to count as well. Firstly, the joints resulting from brazing are less stronger in comparison to the welding method. Moreover, the fluxes used in brazing have some quantity of toxic components promoting harmful impact.

Lastly, the joints processed from the brazing process aren’t suitable for high-temperature applications.

What is Soldering?

The soldering process requires melting solders from soldering iron. Therefore, soldering is carried out at comparatively low temperatures compared to the brazing method. This much-loved method takes place in the presence of solder that melts at 450 C. After melting the solder; people use it to form a bond between the metal pieces.

Its melted solder making a bond between two metals isn’t as strong as the brazed and welded ones. Therefore, strength and tightness are somewhat compromised when it comes to the soldering method in particular.

The soldering method does offer wonderful flexibility, just like brazing in particular. The metals compatible for soldering purposes are gold, brass, copper, and iron, etc. Furthermore, soldering incorporates fluxes in the process, just like its relative methods like brazing and welding.

The people use fluxes to clean up the metal surface. At the same time, fluxes offer convenience for the solder to flow above the metal pieces that will be joined together. Soldering finds its large applications in the industry of electronics in particular.

Though the joint results from soldering aren’t really tight and strong but are still trusted to join electrical components, it electrically connects to the conductive solder. Therefore, it has wide usage in the electronic industries for sure.

There was a time when filler having lead-based materials were used, but this trend is no more and changed. Due to environmental concerns, industries are shifting towards lead-free filler materials in the soldering process.

Advantages of Soldering:

Even lower power input and the temperature in the process compared to the welding and brazing methods. Also, welders can join different base materials, unlike with welding method. Welders can also join thin-walled parts with the soldering method.

Similarly, there’s no post-heat treatment required when it comes to this method. Moreover, you won’t experience thermal distortion and residual stresses with the soldering method.

Disadvantages of Soldering:

Underpowered joint strength highlights the main difference between welding and soldering. This makes it unsuitable for load-bearing structures. Adding more, welders won’t be able to join the large sections of the metals.

The fluxes used in soldering might contain harmful substances, just like the brazing method. At last, soldering joints are comparatively unsuitable for high-temperature applications.

Final verdict

We’ve seen the great disparities between the welding, brazing, and soldering methods from the above discussion. They all provide different necessities to different individuals. Therefore, it’s tough to specify a clear winner as each method serves a specific purpose.

But still, brazing is our personal favorite because of its incredible flexibility and fair strength. Also, it offers minimum thermal distortion and residual stresses. You won’t be providing it a post-heating treatment making its processing sublime.

From the light of the above features, we can assure you that, brazing method will suit most applications without a doubt.

Are soldering and brazing the same methods?

Soldering differs from brazing mainly in terms of temperature disparity. Soldering requires low temperature and power input as compared to the brazing method.

Which method of all offers the strongest joint?

It’s welding, being the most popular among all, and has been used for a long time now. It certainly offers the strongest metal joint.

Which methods offer to join dissimilar metals?

Brazing and soldering offer the joining of dissimilar metals, unlike the welding method.

![Body Panel Adhesive VS Welding [Guide & Suggestions] Body Panel Adhesive VS Welding [Guide & Suggestions]](https://welding-world-awards.com/wp-content/uploads/2023/12/60db234c-1db6-460e-9ea5-eaeffc77f0ed-768x576.jpg)