Disclaimer: We support our readers with industry knowledge & research. You support us through our carefully chosen products with links that may earn us a commission.

Cast iron makes a good percentage of our home accessories. It may liable for crack and rust with the passage of time. All this is due to its brittle and unique surface. The cracking behavior does not mean that you should not use cast iron in the composition. So, it is not a solution at all.

So, what is an excellent alternative?

You should deal with the situation instead of cutting down its use. No doubt, these may get a break from drop or shock from thermal temperature. But, there are multiple options for this fixing.

You have no need to worry as we have brought for you a solution on how to fix cast iron without welding. We are quieting welding here because it may leave cast iron further damaged.

Hence, we are going to introduce the best alternative, brazing here.

How to fix cast iron without welding?

The following steps are helpful in fixing the cast iron without welding it:

Step- 1 Choose a filler rod

Pick the filler rod according to the part of cast iron needed to fix. Keep in mind, that brass and nickel offer the main constructional element of the filler rod as they are set with the cast iron. It is your choice whether you use a flux-containing rod or separate flux.

Step-2 Clean the surface

Next, you have to clean the surface of the disturbing parts. This is necessary to remove dust, impurities, and oxide.

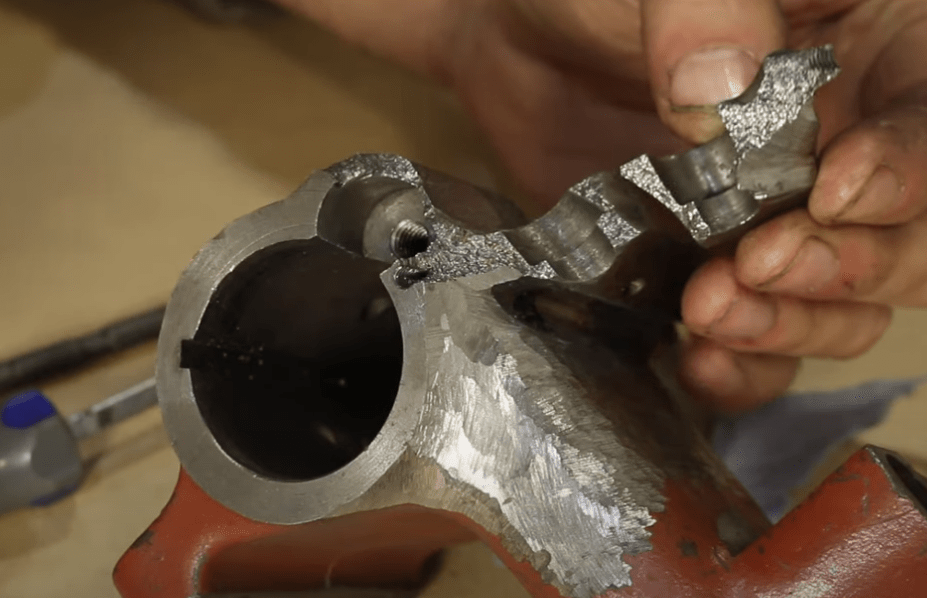

Step- 3 Ground the crack

Get the favor of the grinder and let the crack ground. Change the crack section to the U-shaped representation. This process is necessary to bypass the stress and let the brazing material fill the space correctly.

Step- 4 Brush the surface

Paint the ground area with the stainless stain brush. This step is needed to get rid of all the impurities left on the surface.

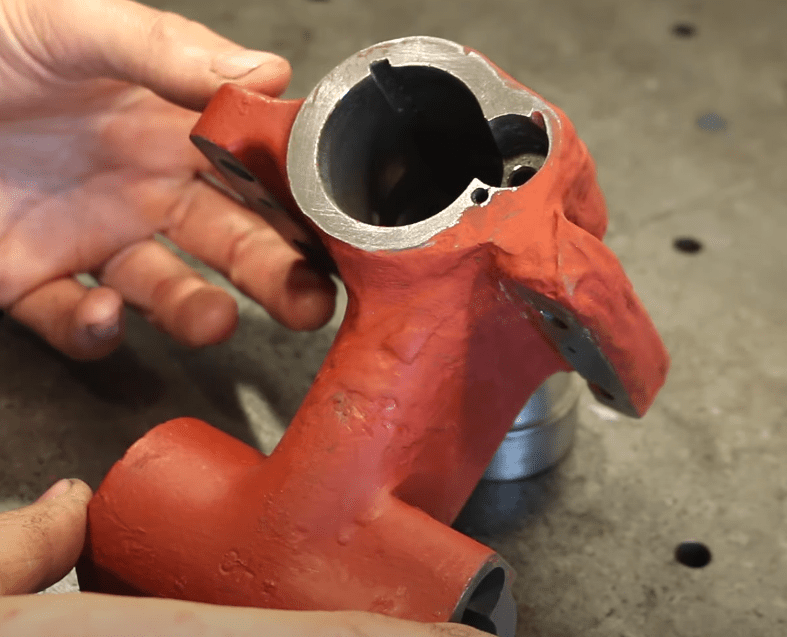

Step- 5 Heat the parts

You can now heat the parts of cast irons with good confidence. At this step, try to avoid brazing the torch on cooler parts. It may crack the parts more. Ensure the heating by using any appliance from grill to burner and oven.

Step-6 Brace the parts

Lift the cast iron from the heating surface place and place it on the work surface. Have a good observation and brace it if required. In addition, if the surface of iron is suffering from wider cracks heat it during bracing. But, this process would take a longer time to meet the required results.

During work, try to maintain the temperature of the unit by using an external heater. It would let the whole procedure too simple.

Step-7 Get a bright red surface

You can warm the iron surface by brazing the torch until it gets red hot. Check the temperature of the filler rod and let it flow into the cracks to fill it completely. During this process, the temperature should be maintained to ensure continuous flow.

Step- 8 Cover the parts

At this step, place the parts in the box of sand and let it cover completely. These parts should be cooled slowly afterward. Try to avoid cooling it in the open air. This practice increases the chances of cracking. Leave the fixed iron part in the sand and let it place here or more in the sand according to the crack size.

Final Verdict

So, we have discussed how to fix cast iron without welding with all the prominent steps. These steps are not difficult to follow. Some delicate steps should be followed with care.

Moreover, never forget to have some safety precautions for this procedure. You can have gloves, helmets, boots, and other elements to ensure your safety.

No doubt,

Many other procedures are available to follow, but we have discussed the most prominent and famous procedure. So, the steps we have mentioned will allow you to work flawlessly.

According to experts, the brazing system is the most famous one that has good results. That’s why a large number of users prefer this procedure.